The vibrant hum of a hydraulic press, the crisp aroma of freshly harvested greens, the silent power of a high-pressure chamber – this isn't your grandma's juice bar. We're talking about a sophisticated ecosystem where Organic & Specialty Juice Production is pushing the boundaries of what's possible in the beverage industry. It’s a space where health, purity, and cutting-edge technology converge, offering consumers not just a drink, but a nutrient-dense experience crafted with meticulous care.

In an era where consumers scrutinize ingredient lists and demand transparency, organic and specialty juices have emerged as a beacon of mindful consumption. They represent a commitment to environmental stewardship, a dedication to superior nutrition, and often, a celebration of local agriculture. But what exactly goes into crafting these premium beverages, and how do producers ensure they deliver on their promise of purity and potency? Let's dive in.

At a Glance: The Pure Essence of Organic & Specialty Juice

- Purity First: Organic juices are free from synthetic pesticides, herbicides, and fertilizers, guaranteed by a minimum of 95% organic ingredients.

- Nutrient Retention Kings: Methods like Cold Pressing and High-Pressure Processing (HPP) preserve up to 100% of vital nutrients, unlike traditional heat pasteurization which can lose 40-60%.

- Extended Freshness: HPP naturally extends shelf life to 40-60 days without chemical preservatives, ensuring a longer window for enjoyment.

- Local Love: Many producers prioritize sourcing from local organic farms, strengthening communities and reducing carbon footprints.

- Innovation Hotbed: Expect exciting seasonal flavors, unique ingredient combinations, and functional juices packed with superfoods and probiotics.

- Strategic Partnerships: Choosing the right manufacturing partner (co-packer) is crucial for scaling, ensuring quality, and navigating complex production methods.

- Growing Market: Consumer demand for health-focused, natural beverages is fueling an 8.5% projected CAGR, highlighting a booming future.

The "Organic" Edge: More Than Just a Label

When a bottle proudly bears the organic seal, it's signaling a profound difference from its conventional counterparts. This isn't just about a marketing buzzword; it’s a commitment to a set of stringent standards that impact everything from soil health to your cellular health.

Defining Organic: A Promise of Purity

At its core, organic juice production is about ingredient purity. It demands that the fruits and vegetables used are grown without synthetic pesticides, herbicides, or fertilizers. This isn't merely a preference; it’s a legal requirement. For a juice to be labeled "organic," it must contain at least 95% organic ingredients. The remaining 5% must come from a USDA-approved list of non-organic ingredients that are not commercially available in organic form.

This focus extends beyond the farm. Organic certification also dictates how the juice is processed, requiring careful segregation from non-organic products and prohibiting the use of artificial colors, flavors, or preservatives. It’s a holistic approach designed to deliver a cleaner, healthier product from seed to sip.

Why Organic Matters: A Ripple Effect of Benefits

The choice to go organic creates a positive ripple effect that touches environmental sustainability, economic viability, and, ultimately, consumer health.

- Environmental Stewardship: By avoiding synthetic chemicals, organic farming practices protect biodiversity, promote healthy soil, conserve water, and reduce pollution. It's a system designed to work with nature, not against it.

- Enhanced Nutritional Value: While all produce is good, organic produce often boasts higher levels of certain vitamins, minerals, and antioxidants. When processed using methods that preserve these delicate compounds, the nutritional advantage of organic ingredients truly shines. Imagine a bottle of organic green juice, crafted from 100% organic vegetables, often packing over two pounds of high-nutrient ingredients per bottle – that’s a significant boost to your daily intake.

- Boosting Local Economies and Communities: Many organic juice producers prioritize local sourcing. This isn't just a trend; it's a foundational principle that fosters community connections, upholds transparency, and significantly boosts regional agriculture. For example, a company like Organic Squeeze buys 9 tons of organic produce monthly and plans to increase that significantly, making organic options more accessible in areas where organic agriculture is still a small percentage of the total, like Virginia. This commitment directly supports local organic farms and suppliers, creating new retail opportunities and encouraging wider adoption of sustainable practices. It creates a vibrant ecosystem where businesses and farms grow together.

- Transparency and Trust: The organic label isn't easily earned. It requires rigorous certification processes, regular inspections, and transparent labeling practices. This gives consumers confidence that what they're drinking aligns with their health and ethical values.

Beyond Conventional: What Makes Specialty Juice Stand Out?

While "organic" defines the ingredients, "specialty" often refers to the sophisticated methods and innovative approaches used to transform those ingredients into exceptional beverages. This is where advanced techniques ensure maximum nutrient retention, extended freshness, and truly unique flavor profiles.

Nutrient Powerhouse: The Magic of Cold Pressing

Forget the whirring blades of a centrifugal juicer that generate heat and oxidize precious nutrients. Specialty juice production often begins with cold pressing. This innovative method uses a hydraulic press to slowly and powerfully extract juice from fruits and vegetables.

Here's why it's a game-changer:

- No Heat, No Oxidation: Unlike traditional juicing methods, cold pressing generates minimal heat and friction, which are notorious for destroying delicate enzymes, vitamins, and minerals.

- Maximum Yield & Density: The hydraulic press squeezes every last drop of nutrient-rich liquid from the produce. This efficiency often means that a single bottle of cold-pressed juice contains the nutritional equivalent of over two pounds of raw produce.

- Vibrant Flavor: With minimal exposure to heat and air, the natural flavors and aromas of the ingredients are preserved, resulting in a cleaner, more vibrant taste experience.

The HPP Advantage: High-Pressure Processing for Purity and Longevity

Even the most meticulously cold-pressed juice needs a way to remain safe and fresh on the shelf. Traditionally, this involved heat pasteurization, a process that, while effective at killing pathogens, also degrades heat-sensitive nutrients and alters flavor. Enter High-Pressure Processing (HPP).

HPP is an innovative, non-thermal preservation method that utilizes immense water pressure instead of heat. Here’s how it works and why it’s transformative for specialty juice:

- How it Works: Packaged juice (usually in a flexible bottle) is submerged in a chamber filled with water. This water is then pressurized to extremely high levels (up to 87,000 psi, or six times the pressure at the deepest part of the ocean). This pressure is uniformly transmitted throughout the product, inactivating bacteria, yeasts, and molds without altering the product’s fresh characteristics.

- Unrivaled Nutrient Retention: This is where HPP truly shines. By avoiding heat, HPP preserves 100% of the vitamins, enzymes, and antioxidants that would otherwise be lost in traditional thermal pasteurization (which can account for a 40-60% nutrient loss).

- Extended Shelf Life, Naturally: HPP significantly extends the shelf life of cold-pressed juices to 40-60 days when refrigerated, all without the need for artificial chemicals, additives, or preservatives. This transparency in labeling is a huge win for both producers and consumers.

- Enhanced Food Safety: By eliminating harmful pathogens, HPP provides an added layer of food safety, giving consumers peace of mind.

- Preserved Flavor and Texture: Because there’s no heat involved, the fresh taste, color, and texture of the juice remain virtually unchanged, delivering a product that truly tastes "just made."

The growing importance of HPP for nutrient retention and extended shelf life without preservatives is a key trend, reflecting increasing consumer demand for health-focused, natural beverages.

Innovation in a Bottle: Flavor, Function, and Form

Specialty juice production isn't just about preserving what nature provides; it's also about elevating it through creative innovation. Producers are constantly experimenting to deliver exciting new experiences:

- Seasonal Flavor Innovations: Drawing inspiration from local culture and heritage, companies are developing unique ingredient combinations that reflect the freshest produce of the season. This might mean a limited-edition summer blend featuring watermelon and mint, or a warming turmeric and ginger shot for colder months.

- Functional Juices: The rise of functional foods has fully extended to juice. These beverages feature "superfoods," adaptogens, or probiotics, designed to deliver specific health benefits beyond basic nutrition. Think juices with spirulina for detoxification, reishi mushroom for immunity, or live probiotics for gut health.

- Unique Ingredient Combinations: Beyond the classic orange or apple, specialty juices often blend unexpected fruits, vegetables, herbs, and spices to create complex, balanced, and invigorating taste profiles.

Whether you're looking for a quick vitamin boost or exploring a new flavor sensation, the specialty juice market is continuously evolving to meet diverse consumer needs. Many consumers are actively seeking out such unique options, perhaps even searching for specific brands like Find Juice Generation nearby to discover the latest offerings.

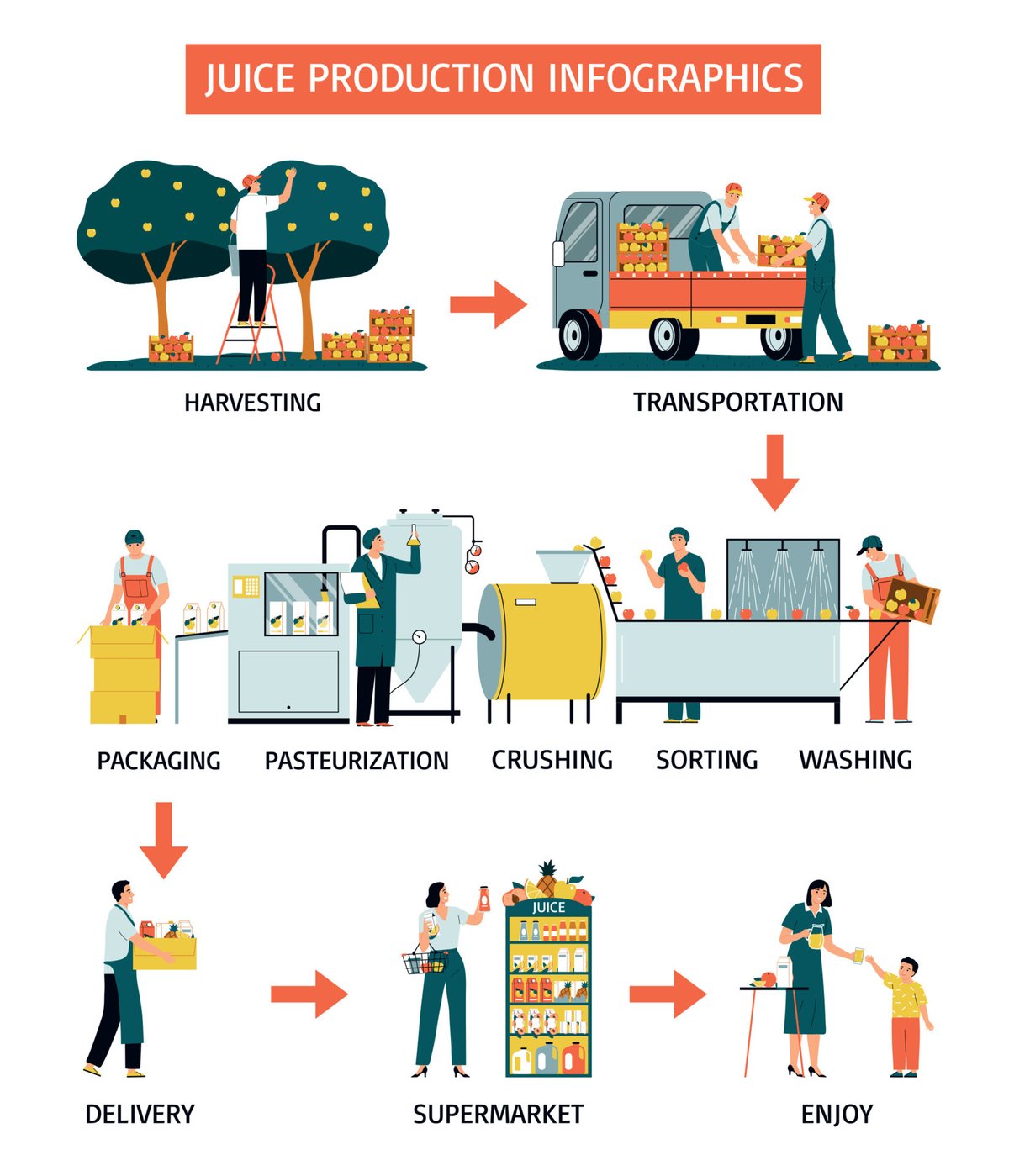

Bringing Your Vision to Life: The Production Journey

From the moment an idea sparks for a new juice blend to its arrival on store shelves, the journey is intricate and demanding. It requires meticulous planning, stringent quality control, and often, strategic partnerships.

From Farm to Bottle: Ensuring Ingredient Integrity

The foundation of any exceptional organic and specialty juice is, of course, its ingredients. This phase involves:

- Meticulous Sourcing: For organic juices, this means partnering with certified organic farms, often local, who adhere to strict guidelines. For specialty juices, it extends to finding unique, high-quality ingredients, whether that's exotic fruits, potent herbs, or rare vegetables.

- Quality Control at Receiving: Upon arrival, produce undergoes rigorous inspection to ensure freshness, ripeness, and freedom from blemishes or contaminants. This often involves checking Brix levels (sugar content), pH, and visual quality.

- Washing and Preparation: Ingredients are thoroughly washed and prepared—trimmed, peeled, pitted, or chopped—according to the specific requirements of each recipe and equipment.

The Art of Formulation: Crafting the Perfect Blend

This stage is where science meets artistry.

- Recipe Development: Food scientists and flavor experts work to create balanced recipes that are not only delicious but also nutritionally potent. This involves careful consideration of ingredient ratios, sweetness levels, acidity, and mouthfeel.

- Nutritional Goals: Beyond taste, formulations are often designed to meet specific nutritional targets, whether it's a high vitamin C content, a good source of fiber, or a low-sugar profile.

- Sensory Evaluation: Extensive taste testing and sensory analysis are crucial to refine flavors and ensure consistency across batches.

Navigating the Manufacturing Maze: Choosing the Right Partner

For many emerging brands and even established companies looking to expand, partnering with a juice manufacturing company – often called a co-packer or co-manufacturer – is an essential step. These specialized facilities can handle various stages of product development, from ingredient sourcing to final packaging, allowing brands to focus on marketing and distribution.

Why a Co-Packer? The Power of Specialization

Unless you have the capital and expertise to build your own state-of-the-art facility, a co-packer is invaluable. They provide:

- Expertise: Access to seasoned food scientists, quality control specialists, and production engineers.

- Equipment: Investment in expensive, specialized machinery like cold presses, HPP units, bottling lines, and refrigeration systems.

- Certifications: Compliance with FDA regulations, organic certifications, and other industry standards.

- Scale: The ability to produce small-batch runs for startups or scale up to high-capacity production for growing brands.

The ideal choice of manufacturer isn't a "one-size-fits-all" decision; it fundamentally depends on your specific product and business needs.

Key Decision Criteria: Finding Your Perfect Match

Choosing the right manufacturing partner is one of the most critical decisions you'll make. Here’s what to consider:

- Define Your Product & Needs Precisely:

- Budget: What are your cost constraints per unit?

- Product Details: Is it a fruit base, vegetable blend, concentrate, or fresh-pressed? What additives, if any, are included? Are there unique ingredient handling requirements?

- Volume: What are your desired minimum initial batch sizes? What are your growth projections?

- Current Success: What market traction or sales successes have you already achieved? This detailed information is crucial for manufacturers to respond effectively to your requests.

- Capabilities & Expertise:

- Processing Methods: Do they specialize in cold press? Do they offer HPP? Hot fill lines? Are they capable of handling specific ingredients like superfoods or probiotics?

- Packaging Options: Can they accommodate your desired packaging – glass bottles, PET plastic, cartons, pouches? What about different sizes?

- Certifications: Are they FDA-registered? Do they hold organic certification (USDA Organic)? Are they kosher, halal, or allergen-free certified if relevant to your product?

- Formulation Support: Can they assist with recipe development, shelf-life testing, or nutritional analysis?

- Scale and Flexibility:

- Minimum Order Quantities (MOQs): Some manufacturers, like H.A. Rider & Sons, a family business since 1948, specialize in fruit juice processing for startups and small businesses, offering lower MOQs. Others, like Nor-Cal Beverage Co., founded in 1937, boast high capacity (over 74 million cases/year) with automated blending for precision, catering to larger brands.

- Growth Potential: Can they grow with you? Will they be able to handle increased volumes as your brand expands? Pack Labs, for instance, focuses on wellness products and supports small businesses with small-batch co-packaging and brand development.

- Location & Logistics:

- Consider the proximity of the manufacturer to your ingredient suppliers and target markets. This impacts shipping costs and time. A company like Portland Bottling Company, nearing 100 years of operation, leverages its strategic Pacific NW location for quality and speed. For East Coast needs, Nutrifresh Services offers a large warehouse and aims to be a one-stop-shop.

- Support Services:

- Platforms like PartnerSlate can streamline the search process, connecting brands with manufacturers that have the right expertise and capabilities, saving time and potential consultant fees. Beyond this, look for partners who offer comprehensive solutions, from supply chain management to warehousing. Southeast Bottling & Beverage, with its large 150,000 sq ft FDA-registered facility and over 40,000 gallons capacity, offers turnkey solutions.

What to Expect from Outreach: Be Prepared

Finding the right co-packer requires significant time investment in cold calls, emails, and follow-ups. Be prepared with well-researched, detailed requests. The more specific you are about your product, budget, and needs, the better manufacturers can identify if your project is a suitable fit for their capabilities. Remember, manufacturers are also evaluating you as a potential client, so clear communication and a well-defined vision are key.

Some companies, such as Texas Food Solutions, specialize in processing methods like pasteurization, heating, and mixing to preserve taste, offering flexibility for various production sizes. Others, like West Coast Copacker, INC., handle hot or cold product runs with diverse packaging options (plastic/glass) and custom labeling. The landscape is rich with options, from global scalers like CalPack Foods to those focusing on quality ingredients and fresh concentrates like Eagle Beverage Products.

Quality Control & Compliance: The Unsung Heroes of Purity

Behind every bottle of organic and specialty juice is a robust system of quality control and regulatory compliance. This is where the commitment to purity truly gets tested and proven.

Ensuring Organic Certification

Maintaining organic status is an ongoing process. Producers must:

- Source Certified Ingredients: All ingredients labeled organic must come from certified organic suppliers.

- Prevent Commingling: Strict measures are in place to prevent organic ingredients and products from mixing with non-organic ones during storage, processing, and packaging.

- Adhere to Approved Processes: Only approved processing aids and methods can be used, and synthetic additives are strictly forbidden.

- Regular Audits: Facilities undergo annual inspections by organic certifying agents to ensure continuous compliance with USDA Organic standards.

Food Safety Standards: Beyond Organic

While organic certification ensures ingredient purity, food safety compliance ensures the product is safe to consume. This involves:

- FDA Registration: All juice manufacturers in the U.S. must be registered with the FDA and adhere to Good Manufacturing Practices (GMPs).

- Hazard Analysis and Critical Control Points (HACCP): A systematic preventive approach to food safety that identifies potential hazards (biological, chemical, physical) and designs measures to reduce these risks to a safe level.

- Microbial Testing: Regular testing of raw ingredients, in-process samples, and finished products for pathogens (like E. coli, Salmonella, Listeria) and spoilage organisms.

- Allergen Control: Strict protocols for identifying, separating, and cleaning equipment to prevent cross-contamination of common allergens.

Traceability: Knowing Your Juice’s Journey

Modern food safety and quality systems emphasize traceability. This means being able to track every ingredient from its origin farm through every stage of processing, packaging, and distribution. In the event of a recall or quality issue, full traceability allows for quick identification and resolution, protecting both consumers and the brand's reputation.

The Future is Bright: Trends Shaping the Juice Aisle

The organic and specialty juice market is dynamic, evolving rapidly in response to consumer preferences and technological advancements. Its projected 8.5% CAGR from 2021-2028 underscores a vibrant future.

- Growing Consumer Demand for Health: Consumers are increasingly health-conscious, seeking out natural beverages that offer functional benefits, low sugar, and clean labels. This trend will continue to drive innovation in the specialty juice sector.

- HPP as a Standard: High-Pressure Processing will become an even more ubiquitous method for preserving fresh, nutrient-dense juices, largely replacing thermal pasteurization in the premium segment.

- Hyper-Local Sourcing: The emphasis on locally sourced ingredients will intensify, not just for sustainability but also for freshness and community support. This trend can help make organic options more accessible, especially in regions with growing organic agriculture.

- Rise of Functional Juices: Expect to see even more sophisticated formulations featuring superfoods, adaptogens, probiotics, and other functional ingredients targeting specific health outcomes like immunity, cognitive function, or stress reduction.

- Eco-Friendly Practices: Producers will continue to prioritize sustainable packaging (e.g., recycled PET, glass, biodegradable materials), waste reduction, and energy-efficient production methods to appeal to environmentally conscious consumers.

Common Questions About Organic & Specialty Juice Production

Let's address some common queries you might have.

Is organic juice really more nutritious?

Yes, often. Organic produce, grown without synthetic pesticides and fertilizers, can retain more nutrients compared to conventionally grown produce. Furthermore, the specialized production methods like cold pressing and HPP used in specialty juice production are specifically designed to preserve these nutrients, avoiding the significant losses seen with traditional heat pasteurization. So, combining organic ingredients with these advanced methods generally yields a more nutrient-dense product.

What's the difference between cold-pressed and HPP?

Cold-pressed refers to the method of extracting the juice from fruits and vegetables using a hydraulic press, minimizing heat and oxidation to preserve nutrients. HPP (High-Pressure Processing) is a preservation method applied after the juice has been cold-pressed and bottled. It uses high water pressure to inactivate pathogens and extend shelf life without heat, thereby protecting the nutrients that the cold-pressing method so carefully retained. They are complementary processes.

How long does organic juice last?

The shelf life of organic juice depends heavily on the processing method. Unprocessed, truly raw cold-pressed organic juice typically lasts only 3-5 days under refrigeration. However, with HPP, the shelf life can be extended significantly to 40-60 days when kept refrigerated, without the addition of chemicals or preservatives. Always check the "best by" date on the bottle.

Is it more expensive to produce organic juice?

Generally, yes. The cost of organic produce is higher due to more labor-intensive farming practices, smaller yields, and the certification process. Additionally, the specialized equipment required for cold pressing and HPP represents a significant investment. However, this higher cost reflects the superior quality, nutritional integrity, and environmental benefits that consumers are increasingly willing to pay for.

Your Next Sip: Empowering Healthier Choices & Sustainable Growth

The world of organic and specialty juice production is a testament to innovation driven by health-conscious consumers and dedicated producers. From the meticulous care taken in sourcing pesticide-free ingredients to the marvels of High-Pressure Processing that lock in nutrients, every step is designed to deliver a superior beverage.

Whether you're a consumer seeking peak nutrition and unique flavors or an entrepreneur looking to enter this dynamic market, understanding these advanced methods and the values they represent is key. The future of juice is pure, potent, and passionately crafted – ready for you to enjoy.